Author = Ibrahim, Abbas F.

Number of Articles: 3

Influence of Machining Parameters on Surface Roughness in Chemical Machining of Silicon Carbide (SiC)

Volume 40, Issue 6 , June 2022, , Page 879-884

Abstract

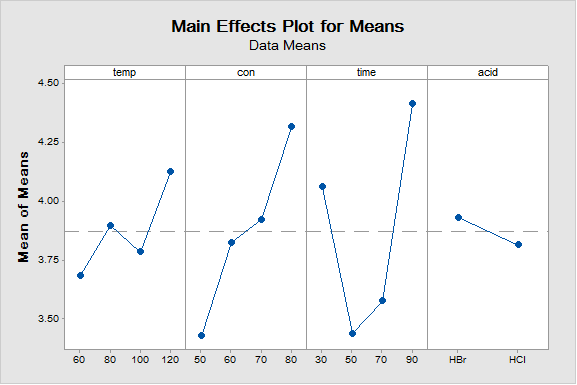

This study discussed the influence of chemical machining parameters such as (machining time, type of etchant, etching temperature, and concentration of the solution) on the surface ... Read More ...Effect of Machining Parameters on Surface Roughness and Metal Removal Rate for AISI 310 L Stainless Steel in WEDM

Volume 40, Issue 1 , January 2022, , Page 181-188

Abstract

Wire electrical discharge machining (WEDM) is a non-traditional machining process that is widely used in the machining of conductive materials. This paper presents the investigation ... Read More ...Enhancement of EDM Performance by Using Copper-Silver Composite Electrode

Volume 38, 9A , September 2020, , Page 1352-1358